Add to Cart

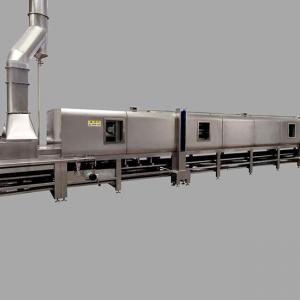

Energy Saving Water Sealed Multi Layer Noodle Steaming Machine Compact Structure

Henan Dongfang Noodle Machine Group Co., Ltd. was founded in 1975. Dongfang has passed ISO9001 certification, its products have obtained the CE international standard certification and more than 40 innovative products have obtained the invention or utility model national patents, leading the technical trend of the noodle machine industry.

Main Structure:

The machine is a multi-layer structure, which can greatly shorten the length of the equipment and reduce the steam consumption compared with the single layer.It is mainly composed of frame, box body, box door, conveying network, steam pipeline and steam cylinder. The box body and box door are made of high-quality thermal insulation materials with thick layers of stainless steel plates. The door and the box are sealed with non-toxic rubber, and the good heat preservation and sealing can save energy.

Technical Parameters:

|

Product Name |

Multi Layer Noodle Steaming Machine |

|

Production Capacity |

40000pcs-280000pcs/8hours |

|

Material |

Stainless Steel 316 |

|

Length |

7.8-11.8m |

|

Feature |

3 layer individual steam in, water sealing |

|

Automatic Grade |

Automatic |

Working Process:

The noodles are sent into the steaming box from the outer steaming mesh. In the first temperature zone, the temperature is initially heated up, the dough strips run to the second temperature zone to maintain high temperature gelatinization, and the noodle are gelatinized and shaped by running to the third temperature zone. Then run to the cut-off sorter. The power of the steaming net comes from the cutting machine.